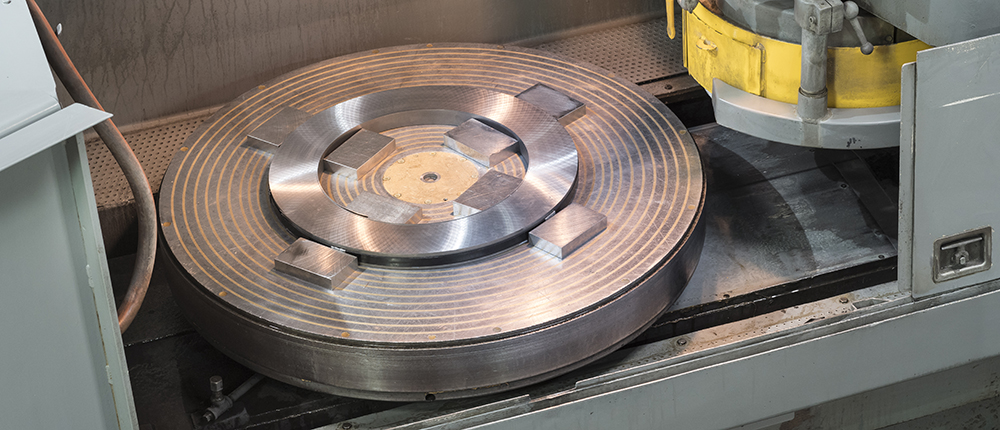

Blanchard Grinding

Blanchard grinding that delivers fast material removal and uniform results, with the capacity to handle large parts efficiently and accurately.

Surface Grinding

Surface grinding that offers tight tolerances and a smooth finish, machined by skilled operators and

reliable turnaround times.

Equipment Capabilities

Rotary Grinding

- 12x Mattison & Blanchard rotary grinders

- 42”, 48”, 54” and 60” gear-drive and high-column machines

- Capable of grinding up to 36” height above table

- .0001” resolution scales with variable speed retrofitted to many of the tables and spindles

- Tolerances of .0005” flat and parallel are possible across entire range of sizes

Large Blanchard Grinding

- 84″, 96″, & 100″ gear-drive and high-column machines

- Can swing parts a maximum of 128″ in diameter

- Capable of grinding up to 65″ height above table

- Hand scraped and aligned table and column ways for maximum accuracy

- Tolerances exceeding .001″ flat and parallel are possible up to the maximum swing envelope

Mattison 400S Plate Grinder

- 36” x 240” magnetic table with a 42” 250HP grinding chuck

- Maximum part profile is 42”wide x 252”long x 24” high, and up to 15,000 lbs.

- Excellent for significant stock removal while still maintaining better than .003” accuracy

Surface Grinding

- Two dozen surface grinders ranging in size from 12” x 24” up to 36” x 168”

- Maximum part profile is 40” wide x 174” long x 35” high, and up to 10,000 lbs.

- Capable of tolerances exceeding .0001” flat and parallel

- Able to grind compound angles, vee ways, dovetails, and most linear geometry

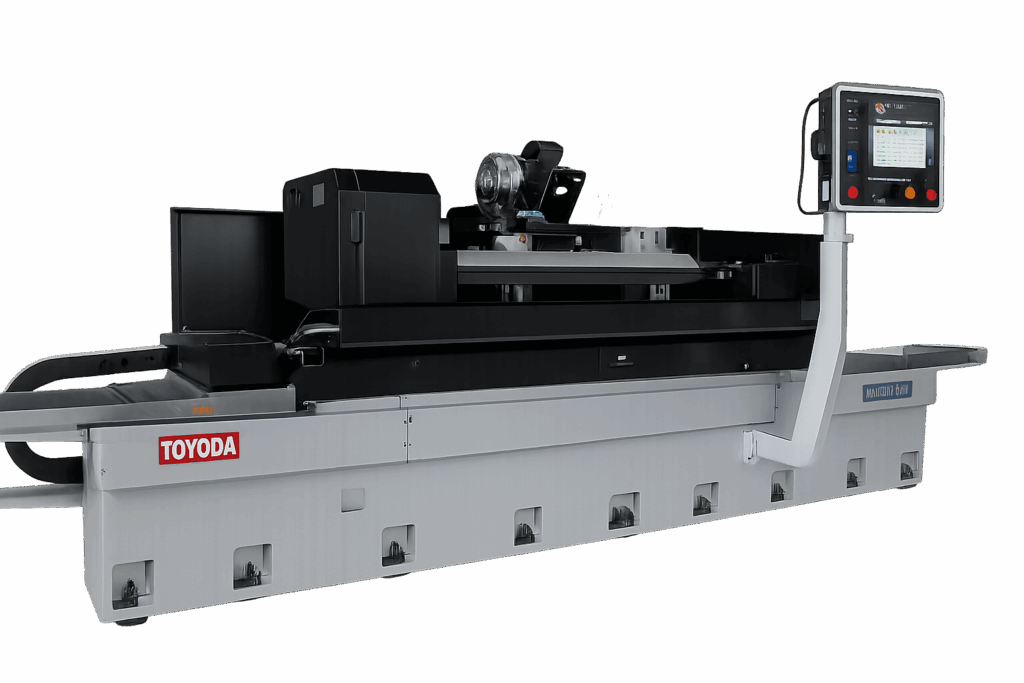

OD Grinding

- Landis and Toyoda OD grinders up to 24” swing, 144” long

- CNC controls for multiple diameters in a single-setup

- Capable of compound tapers and multiple angles, depending on geometry

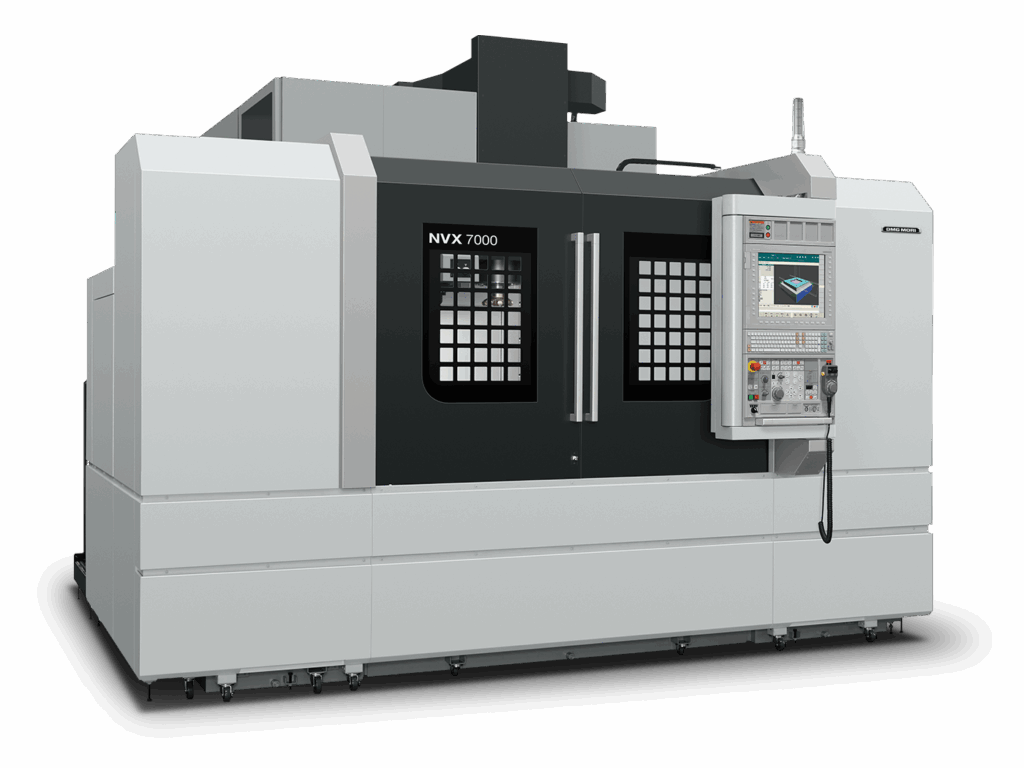

CNC Milling/Turning

- Multiple 3-axis 50-taper vertical CNC milling centers, up to a 60” x 30” x 26” X/Y/Z work envelope

- Live tool lathes, with a 35” maximum swing and 56” maximum length

- Standard tolerances of +/-.001”

- Emphasis on milling and turning hardened alloy/tool/high-speed steels

- Experience with exotic/nickel-alloy machining

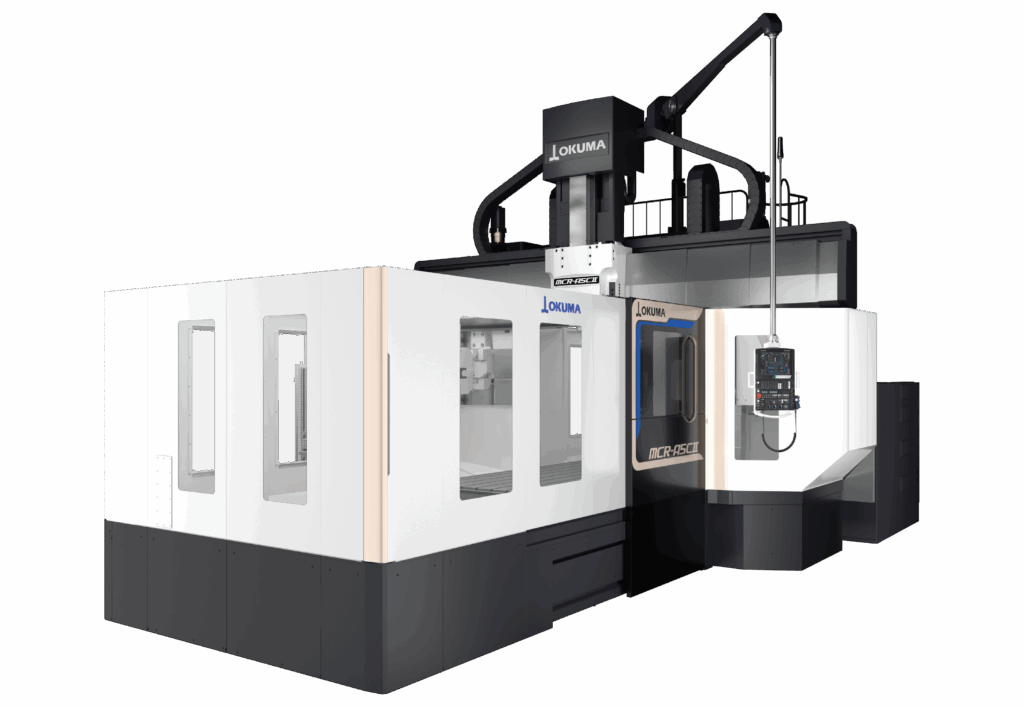

Large Format CNC/5-Axis Milling

- Okuma Double-Column Bridge mill with a 160” x 74” x 48” X/Y/Z work envelope

- 5-degree auto-indexing head for complex 5-side machining in a single setup

- Soraluce 5-Axis horizontal ram mill with a 137” x 51” x 62” X/Y/Z work envelope

- Capable of full-simultaneous 5-axis contour milling

- Equipped with 66” table (90” swing) VTL vertical turning/milling table

Industries We Serve

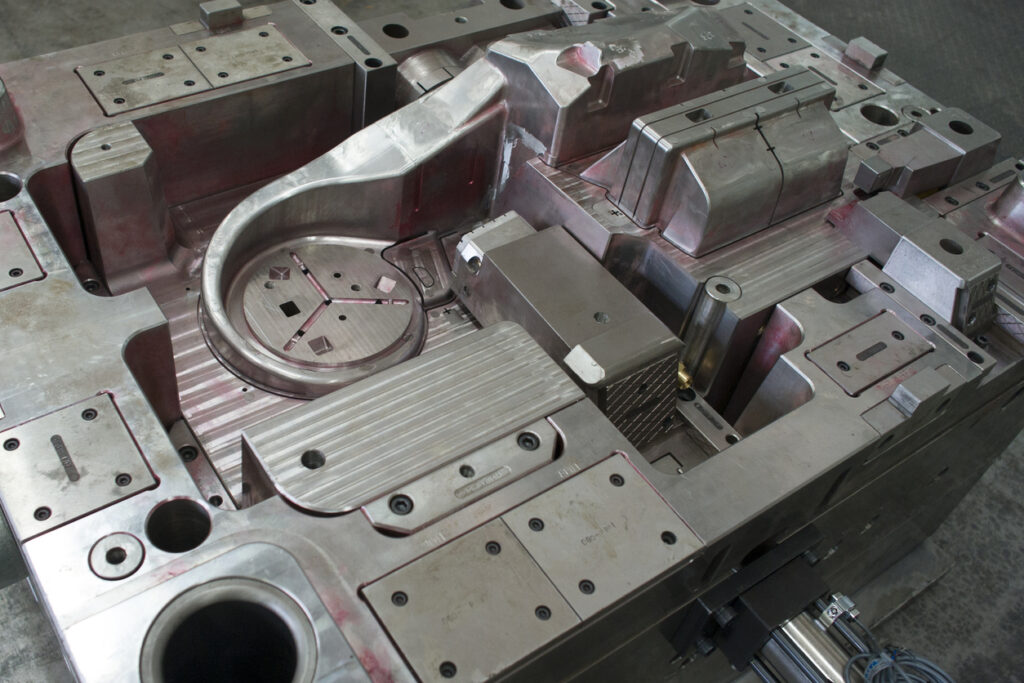

Contract Manufacturing

Heavy Equipment

Paper / Converting

Recycling

Steel / Aluminum

Tool & Die

About Us

Midwest Grinding was established as a local Milwaukee contract grinding shop dedicated to precision Blanchard and specialty surface grinding small to extra-large components. Over the years, Midwest Grinding has enjoyed a reputation as problem solvers, fine tolerance grinders, and specialty surface finish providers.

Our Promise of Value

- Quick Order Turnaround

- Engineering and Technical Support

- Small to Extra Large Part Capability

- Close Tolerance Capability

- Competitive Pricing

- Certified Part Inspection Capability

- In-Process Quality Assurance

- Order Pick-Up and Delivery Service

Photo Gallery

Loading…